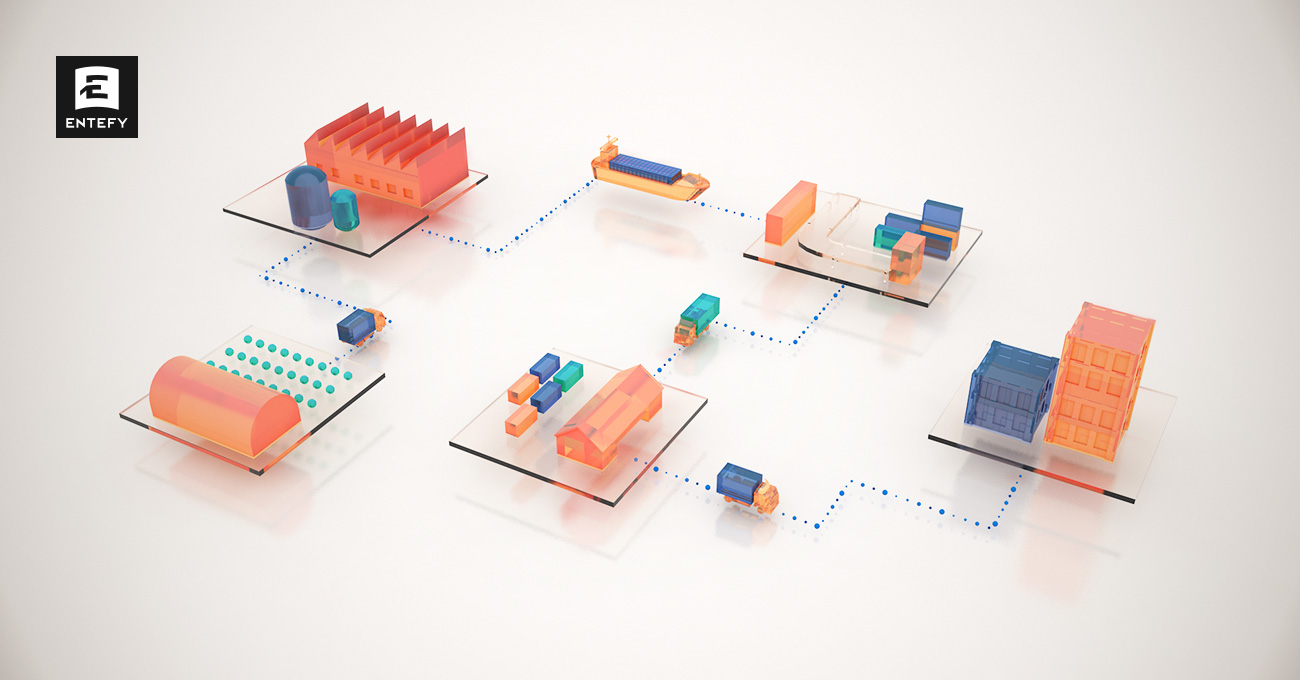

For years, many Americans have consumed a vast, world-class variety of products on a day-to-day basis without necessarily thinking too much about the complex supply chains involved in these products.

All of that changed dramatically with the onset of the COVID-19 pandemic. Suddenly, critical factories and assembly lines came to a halt around the world while shipping containers were stranded at ports due to restrictions from lockdowns and travel bans. For the first time, a majority of the population became painfully aware of the incredible power the global supply chain has on everyday life. More than two years after the pandemic’s start, we continue to feel the impact of these supply chain disruptions via rising costs, product and inventory shortages, delivery delays, and dramatic shifts in consumer behavior. Add a growing number of extreme weather and geopolitical events to the mix and witness the global flow of goods face greater instability.

The best way to address this increasingly complex and volatile trade environment is to work smarter, not harder. And, that is where artificial intelligence (AI) and automation come in.

Supply chain professionals around the world are rapidly adopting AI and machine learning technologies to help them adapt and thrive in the midst of emergent uncertainty. According to IDC, automation using AI will drive “50% of all supply chain forecasts” by 2023. Further, by the end of this year, “chronic worker shortages will prompt 75% of supply chain organizations to prioritize automation investments resulting in productivity improvements of 10%.”

Here are a few examples of how AI and automation are already transforming the supply chain:

Predictive analytics for delivery and warehousing

One of the great ways AI is impacting the supply chain is via advanced analysis of data generated by the Internet of Things (IoT). Thanks to GPS (Global Positioning System) tracking, IoT sensors placed on raw materials, shipping containers, products, as well as communications throughout the logistics pipeline, providers now have real-time visibility into the movement of their goods. Better yet, advancements in machine learning over the last decade have allowed AI to use voluminous, complex data from shipments and IoT devices to accurately predict the arrival of packages and even monitor the storage conditions of products and raw materials.

AI-enabled dynamic routing is helping companies optimize delivery and logistics leading to significant cost savings and efficiency. UPS, for instance, has employed its on-road integrated optimization and navigation (ORION) system “to reduce the number of miles traveled, fuel consumed, and CO2 emitted.” And the impact is tangible. “According to UPS, ORION has saved it around 100 million miles per year since its inception, which translates into 10 million gallons of fuel and 100,000 metric tons of carbon dioxide emissions. Moreover, reducing just one mile each day per driver can save the company up to $50 million annually.”

Use of predictive analytics in warehousing is gaining adoption as well. Many consumers have personally experienced or observed AI leveraging vast amounts of digital data in order to make predictions. We may see this when an e-commerce service tries to anticipate a consumer’s next purchase using historical data. What we sometimes forget is that all this consumer data is tremendously helpful to warehouses and brick-and-mortar stores, which use machine learning and predictive analytics to determine which items will sell in a given week and where those items should be stocked.

Machine learning for streamlining processes and reducing human error

Machine learning also helps with the more technical and time-consuming aspects of moving products around the world. According to a recently published joint report by the World Trade Organization and the World Customs Organization, customs authorities have already embraced advanced technologies such as AI and machine learning. “Around half use some combination of big data, data analytics, artificial intelligence and machine learning. Those who do not currently use them have plans to do so in the future. The majority of customs authorities see clear benefits from advanced technologies, in particular with regard to risk management and profiling, fraud detection and ensuring greater compliance.”

AI has been able to automate the completion of lengthy international customs and clearance forms, providing accurate tallies of products in shipments, correcting mistakes made by human officials regarding country of origin or gross net weight, and providing a customs entry number when a shipment finally arrives at its destination country. Machine learning can also parse out shipment invoices and correctly load the data into a company’s accounting system.

Additional specific use cases include AI systems and applications that help automate supply chain processes and workflows in smart ways. For example, Entefy’s Mimi Ai Digital Supply Chain Hub which is used to optimize logistics, costing, sourcing, and strengthen supplier relationships. With such AI-powered tools, users can automate repetitive manual procedures, reduce errors, track key metrics in real-time (and in one place), and monitor the global supply chain across geographies, business units, vendors, suppliers, and products. Moreover, users can quickly uncover valuable business-critical insights from complex data streams that would be otherwise unfeasible via traditional manual analysis.

Automated decisions and demand forecasting

Producing, packaging, delivering, and selling products today are meeting new sets of customer expectations and behaviors. Simultaneously, the business climate is growing more complex and more volatile, making competition uniquely challenging in times like these. These conditions are leading to digital and AI transformations at an ever-increasing number of organizations worldwide. Supply chain leaders have begun to embrace the need for modernized IT in order to ensure resiliency and efficiency going forward. And this has led to a big shift toward intelligent systems and automation.

According to McKinsey, 80% of supply chain leaders “expect to or already use AI and machine learning” for demand, sales, and operations planning. The overarching objective is to help reduce costs and increase revenue. This is achieved by reducing reliance on human involvement, integrating analytics across the supply chain (from orders to production to demand forecasts), enabling process and workflow automation at virtually every step, and ultimately balancing inventory levels with service levels while reducing lead times from the moment of order to end delivery.

Improved quality control and waste reduction

Quality companies care about quality. For these organizations quality is important to their customers as well as their bottom line. They realize the financial and operational costs associated with poor quality and are taking additional steps to improve quality control and reduce waste.

What is the cost of poor quality? According to ASQ (American Society for Quality), a global membership society of quality professionals in more than 130 countries, costs incurred related to quality related activities “may be divided into prevention costs, appraisal costs, and internal and external failure costs.” It is estimated that quality-related costs are “as high as 15-20% of sales revenue, some going as high as 40% of total operations. A general rule of thumb is that costs of poor quality in a thriving company will be about 10-15% of operations. Effective quality improvement programs can reduce this substantially, thus making a direct contribution to profits.”

The reality is that today with advanced technologies, including AI and machine learning, waste and yield losses due to quality problems are in many ways avoidable. By taking a data-driven approach to the problem, analyzing mountains of data from multiple sources (such as sensors, plant logs, defect reports, service tickets, etc.), companies can better pinpoint hidden issues, quickly identify root causes, and predict (and avoid) vulnerabilities to reduce critical defects and waste. In combination, with AI and automation, companies can increase yields while reducing the overall cost of quality.

Conclusion

The recent disruptions to global supply chains have tangibly impacted the way we produce and consume products—from major delays in product shipments to escalating costs to inventory shortages to the shifts in consumer behavior. Companies have been thrown off balance and as a result have accelerated their adoption of advanced technologies to gain efficiency and resiliency. Using multi-modal machine learning and intelligent process automation to achieve supply chain optimization is something we take pride in at Entefy. Be sure to read our previous blogs about how to begin your Enterprise AI journey and the 18 valuable skills needed to ensure success in enterprise AI initiatives.

ABOUT ENTEFY

Entefy is an advanced AI software and process automation company, serving SME and large enterprise customers across diverse industries including financial services, health care, retail, and manufacturing.